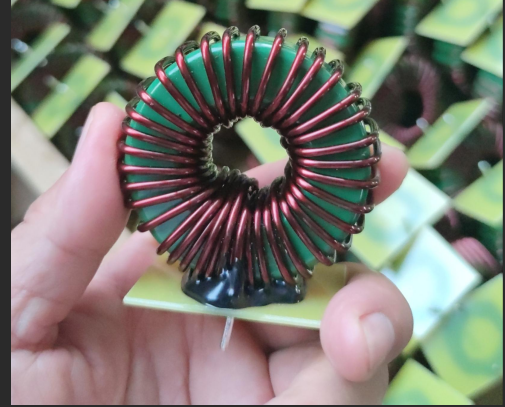

The magnetic ring inductors we commonly use are divided into two types: common mode inductors and differential mode inductors. Common materials used for common mode inductors include manganese zinc high conductivity, nickel zinc, amorphous, nanocrystalline, etc.

Manganese zinc high permeability is generally below 15K and suitable for frequencies below 300KHz. Its main advantage is low cost and suitability for most switch mode power supplies. Its disadvantage is that the Curie temperature is low, the stability at high temperatures is poor, and the winding is also affected by stress, especially for materials above 10K, the inductance deviation is relatively large.

The permeability of nickel zinc is generally below 2K, suitable for frequencies below 1MHz. It can be used as a manganese zinc high conductivity magnetic core to supplement high-frequency filtering.

Amorphous materials are generally suitable for intermediate frequency products between 50-200KHz, with high Curie temperature and magnetic flux density, but overall high cost.

Nanocrystalline materials have high magnetic permeability, and as manganese zinc high conductivity magnetic cores, they can supplement in the direction of high sensitivity, reduce the number of turns of enameled wire winding, and lower the cost of copper wire materials and labor. It also has relatively low losses and good stability at high temperatures, but high costs, making it suitable for high-end products such as automotive, medical, and photovoltaic.

The commonly used materials for differential mode inductors include iron powder core, iron silicon aluminum, iron silicon, iron nickel, iron nickel molybdenum, etc.

Iron silicon aluminum is currently the most widely used differential mode inductor magnetic ring material, with relatively low losses, good saturation magnetic flux density, low cost for mass use, and high universality of specifications. Unless otherwise specified, iron silicon aluminum is preferred for differential mode induction.

Iron powder core has low magnetic permeability, and its main advantage is extremely low cost, but it has a large loss and is only suitable for products with very strict cost requirements. After selection, attention should be paid to loss and heat generation issues.

The main characteristic of iron silicon is its high saturation magnetic flux density, which can be used as a supplement to iron silicon aluminum in terms of anti saturation and loss reduction, but the cost is slightly higher.

Compared to iron silicon, iron nickel has lower losses but higher costs, and is not commonly used in conventional switching power supplies.

Iron nickel molybdenum has the lowest loss, but its anti saturation ability has decreased, and its cost is extremely high. It is mainly used in high reliability products such as military, aerospace, etc.

Post time: Sep-10-2025