As the “heart” of a transformer, the iron core plays a crucial role in electromagnetic energy conversion. It not only affects the energy efficiency performance of transformers, but also directly relates to the volume, weight, and operational reliability of equipment. The evolution of iron core materials, from industrial pure iron to amorphous alloys today, has witnessed the glorious development of transformer technology.

The core function and performance requirements of iron core

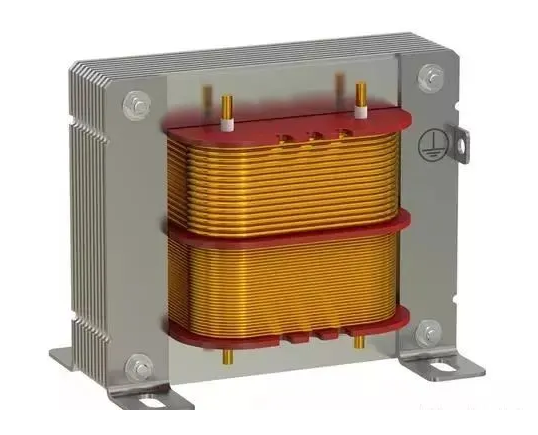

The main function of the transformer core is to provide an efficient magnetic circuit, allowing electrical energy to be transmitted between different circuits through the principle of electromagnetic induction. The performance of the iron core directly affects the technical and economic indicators of the transformer. The basic requirements for iron core materials are: low iron core loss at a certain frequency and magnetic flux density, and high magnetic flux density at a certain magnetic field strength.

The core loss includes two parts: hysteresis loss and eddy current loss. Hysteresis loss is related to the difficulty of material magnetization, while eddy current loss is caused by the circulating current induced by alternating magnetic flux in the iron core. To reduce these losses, ideal iron core materials should have high electrical resistivity, high magnetic permeability, and low coercivity.

The evolution process of iron core materials

The development of transformer core materials has gone through a long and exciting journey. The earliest transformer cores used ordinary carbon steel wire or carbon steel as magnetic materials. In 1885, the Gunz factory in Hungary developed the first single-phase transformer with a closed magnetic circuit, and its iron core was made of this type of material.

In 1900, R.A. Hadfield, an Englishman, and others found that adding silicon to mild steel can improve resistivity, reduce eddy current and hysteresis losses, and alleviate the phenomenon of “core aging”. In 1903, the United States and Germany began producing hot-rolled silicon steel sheets, marking the beginning of the era of silicon steel sheets.

Hot rolled silicon steel sheets have problems such as uneven performance and high losses. In the 1930s, breakthroughs were made in the technology of cold-rolled silicon steel sheets. In 1933, Gauss used two cold rolling and annealing methods to produce 3% Si steel with high magnetic properties along the rolling direction. In 1935, Armco Steel Company of the United States collaborated with Westinghouse Company to begin the production of cold-rolled oriented silicon steel.

After the 1960s, major industrialized countries gradually stopped producing hot-rolled silicon steel sheets and turned to cold-rolled silicon steel sheets with better performance. In 1964, Nippon Steel Corporation of Japan developed high permeability grain oriented cold-rolled silicon steel sheets (Hi-B steel), further reducing the no-load losses of transformers.

In the 1970s, amorphous alloy materials made their debut on the historical stage. In 1974, United Microelectronics Corporation developed iron-based amorphous alloys, and in 1978, the United States developed 10KVA amorphous iron core transformers. This new type of material has the characteristic of extremely low iron loss, only 1/3-1/5 of traditional silicon steel sheets, opening a new era of energy-saving for transformers.

Main types and characteristics of iron core materials

silicon steel sheet

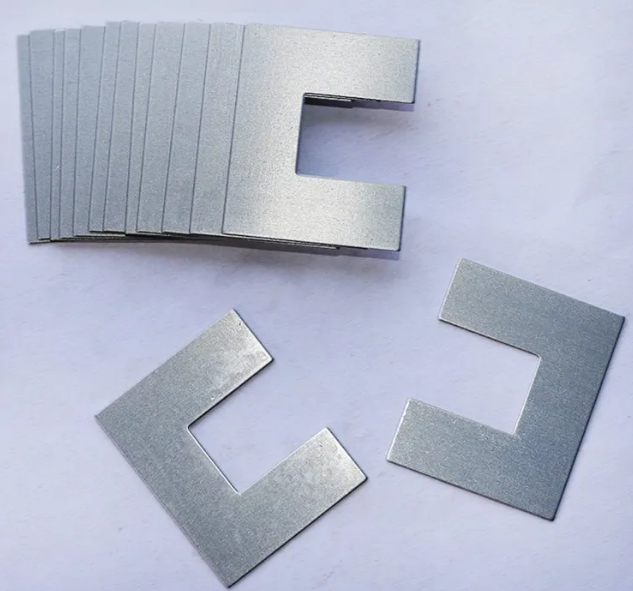

Silicon steel sheet is a soft magnetic alloy of silicon iron with extremely low carbon content, generally with a silicon content of 0.5-4.5%. Adding silicon can increase the electrical resistivity and maximum magnetic permeability of iron, reduce coercivity, core loss, and magnetic aging. Silicon steel sheets can be divided into two categories: hot-rolled and cold-rolled, with cold-rolled being further divided into oriented and non oriented types.

Cold rolled non oriented silicon steel sheet refers to an alloy of 0.5%~4.0% (Si+Al), which is cold-rolled to 0.65mm, 0.5mm, and 0.35mm and then annealed and coated to make it. Its grain texture type is relatively scattered, and it has relatively uniform magnetic properties in all directions.

Oriented silicon steel has high magnetic permeability and low loss characteristics in the easily magnetizable<001>direction, which meets the magnetic conductivity requirements of static power equipment such as transformers. The average grain orientation deviation angle of ordinary oriented silicon steel (CGO) is about 7 °, and the saturation magnetic susceptibility value B8 is above 1.82Tesla; The average grain orientation deviation angle of high magnetic orientation oriented silicon steel (Hi-B) is about 3 °, and the B8 value is above 1.90 Tesla.

amorphous alloy

Amorphous alloy is a metallic functional material with atoms randomly distributed in the material matrix, possessing a “glassy” composition. A typical amorphous alloy contains 80% iron, with the remaining components being boron and silicon. This material has the characteristics of high saturation magnetic induction strength (1.54T), high magnetic permeability, low excitation current, and extremely low iron loss.

The iron loss of iron-based amorphous alloys is only one-third to one-fifth of that of oriented silicon steel sheets, which reduces the no-load loss of amorphous alloy transformers by 70% to 80% compared to traditional silicon steel transformers. The saturation magnetic flux density of amorphous alloys is relatively low (about 1.5T), so the rated magnetic flux density is generally selected as 1.3-1.4T.

The thickness of the amorphous alloy strip is extremely thin, only 0.03mm, resulting in a lamination coefficient of only about 80% for the amorphous iron core. Although amorphous alloys have a lower specific gravity than silicon steel sheets, the weight of the iron core is still relatively heavy.

Core structure design

The design of transformer core structure has also undergone significant evolution. From the earliest laminated iron core, to the C-shaped iron core, and then to the ring-shaped (coiled iron core) iron core, each structure has its own characteristics and advantages.

The circular iron core is made by winding silicon steel strips, like a tightly wound clock spring. This type of iron core has a continuous magnetic circuit without air gaps, resulting in low magnetic resistance and high efficiency. Compared with laminated transformers of the same capacity, toroidal transformers have the advantages of small size, light weight, and low magnetic leakage.

For amorphous alloy transformers, due to the difficulty of cutting their materials, they are usually designed as coiled iron core structures. The core structure of a single-phase transformer is a frame, while the core structure of a three-phase transformer is formed by merging four frames into a structure similar to a three-phase five column structure. This structure enables each phase winding to be placed on two independent frames of the magnetic circuit, effectively eliminating the influence of third harmonic magnetic flux.

Manufacturing process of iron core material

The manufacturing process of silicon steel sheets is complex, especially oriented silicon steel sheets. Its production process is complex, the process window is narrow, and the production difficulty is high. It is known as the “handicraft of steel products”.

The manufacturing process of cold-rolled non oriented silicon steel sheets usually includes: hot rolling steel billets or continuous casting billets into coils with a thickness of about 2.3mm, followed by acid washing, cold rolling, annealing, and insulation film coating processes. For high silicon products, it is necessary to first normalize them at 800-850 ℃ after hot rolling, followed by acid washing, cold rolling to a certain thickness, annealing, then cold rolling at a low reduction rate, and finally final annealing.

The most common method for producing amorphous alloys is to spray molten metal vapor onto a high-speed rotating copper winding frame, and the molten metal is cooled and solidified into thin ribs at a rate of 106 ℃/s. The high internal stress formed by quenching must be reduced by annealing between 200 ℃ and 280 ℃ to obtain good magnetic properties.

Energy saving benefits of iron core materials

Transformers are numerous and have a large capacity in the power system, resulting in considerable total losses. It is estimated that the total loss of transformers in China accounts for about 10% of the system’s power generation. Every 1% reduction in losses can save billions of kilowatt hours of electricity annually.

Amorphous alloy iron core transformers have significant energy-saving effects. The no-load loss of SH12 series amorphous alloy core transformers is reduced by about 75% compared to S9 series silicon steel transformers. Although amorphous alloy transformers are more expensive than traditional transformers, their operating costs are extremely low, and the investment payback period is generally between 2-5 years.

Economically developed regions represented by Shanghai, Jiangsu, and Zhejiang provinces have adopted amorphous alloy transformers on a large scale. Jiangsu Electric Power Company even plans to install new and renovated lines in the future, and the usage of amorphous alloy transformers shall not be less than 30%.

The development trend of iron core materials

Iron core materials are developing towards low iron loss and high magnetic induction. For silicon steel sheets, including non oriented silicon steel for low iron loss high-efficiency motors, thin specification ultra-low iron loss high magnetic induction oriented silicon steel, and high silicon steel for medium and high-frequency energy-saving electrical appliances.

High silicon steel (Si Fe alloy with 4.5%~6.7% Si) has the characteristics of significantly reduced iron loss at high frequencies, high maximum magnetic permeability, and low coercivity. But its Si content is too high, and its plasticity is extremely poor at room temperature, making it difficult to roll and form. At present, non oriented 6.5% Si Fe alloy materials are mainly prepared through silicon infiltration process.

Nano modified materials and bio based materials are also one of the future development directions. With the increasing demand for environmental protection, the development of non-toxic, biodegradable, or recyclable iron core materials will become an important research direction.

Conclusion

The evolution of transformer core materials has witnessed the perfect combination of materials science and electrical engineering. From ordinary carbon steel to silicon steel sheets, and then to amorphous alloys, every material breakthrough has significantly improved the energy efficiency level of transformers.

In today’s world where energy conservation and emission reduction have become a global consensus, the selection of efficient iron core materials is not only related to economic benefits, but also an environmental responsibility. In the future, with the continuous emergence of new materials and processes, transformer cores will continue to develop towards lower losses and higher efficiency, contributing to the construction of a green and low-carbon energy system.

Post time: Aug-29-2025