1.Definition and Principle of Ku

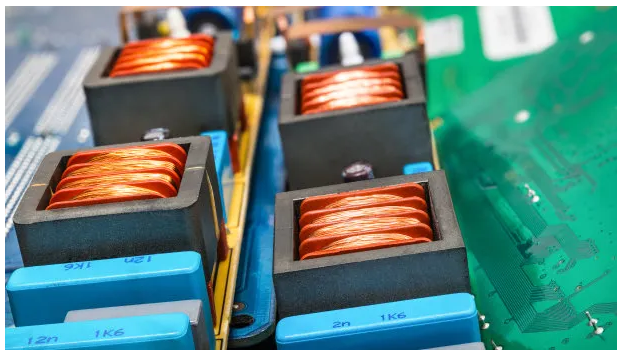

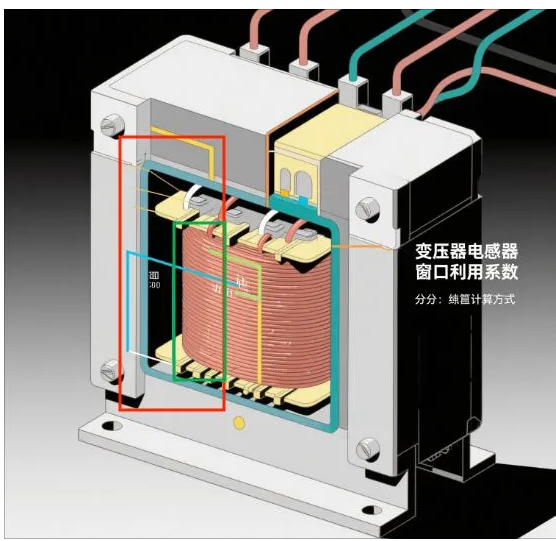

The magnetic cores of transformers and inductors typically have a window area available for winding, and the window utilization coefficient Ku is defined as the ratio of the actual effective area of the winding copper (or aluminum) wire to the total area of the magnetic core window. Expressed as:

Ku=Ac/Aw, Among them, Ac is the total cross-sectional area of the winding wire, and Aw is the area of the magnetic core window. Essentially, Ku reflects the utilization level of the magnetic core window space. The higher the Ku value, the more winding wires can be accommodated in the same window space, which can carry larger currents and improve the power processing capability of electromagnetic components.

The relationship between the window area and the winding can be more intuitively understood through the following diagram:

2.Ku’s calculation method

To calculate Ku, it is necessary to separately determine the total cross-sectional area Ac of the winding wire and the window area Aw of the magnetic core.

Determination: The magnetic core window area Aw can be obtained by measuring the length and width of the magnetic core window, and then multiplying the two. For standard magnetic core models, the window area can also be directly obtained from the data manual provided by the magnetic core manufacturer.

Calculation: Firstly, it is necessary to clarify the number of turns N of the winding and the cross-sectional area a of a single wire. The cross-sectional area a of a single wire can be calculated using the circular area formula a=π d2/4 based on the wire diameter d. So the total cross-sectional area of the winding wire is Ac=N * a. For example, if a transformer uses a magnetic core window size of 50mm in length and 30mm in width, then Aw=50 * 30=1500mm2, winding turns are 100, and a wire with a diameter of 0.5mm is selected. The cross-sectional area of a single wire is a=π * 0.52 ≈ 0.196mm2, Ac=100 * 0.196=19.6mm2, and Ku=19.6/1500 ≈ 0.013

3.Key factors affecting Ku

a. Winding structure

The winding method has a significant impact on Ku. The neat and orderly multi-layer winding method can more efficiently utilize the window space compared to the loose and random winding method, thereby improving the Ku value. For example, using the sandwich winding method (dividing the primary winding into two parts and sandwiching the secondary winding in the middle) can not only optimize the magnetic field distribution, but also improve the utilization of window space to a certain extent.

b. Insulation material

In order to ensure the electrical insulation performance of the winding, insulation materials such as insulation paint and insulation tape need to be used. However, these insulating materials will occupy a certain amount of window space. The thicker the insulation material, the less space is left for the wire, and the Ku value will correspondingly decrease. Therefore, selecting thin and high-performance insulation materials while meeting insulation requirements is an effective way to improve Ku.

c. Magnetic core shape

Different shapes of magnetic cores have varying window shapes and sizes, which can also affect Ku values. For example, compared to toroidal magnetic cores, E-type magnetic cores have more regular windows, making it easier to wind windings and potentially achieving higher Ku values; Although ring-shaped magnetic cores have advantages in electromagnetic shielding and other aspects, winding is difficult, and the utilization of window space is relatively complex. The improvement of Ku value faces more challenges.

4.The importance of Ku in practical design

a. Enhance power density

In the trend of miniaturization and lightweighting of modern power electronic equipment, improving power density has become a key goal. By optimizing Ku, the cross-sectional area of winding wires can be increased within the limited magnetic core window space, allowing for larger currents to pass through and improving the power processing capability of transformers and inductors. In this way, with the same volume, the device can achieve higher power output to meet the increasing power demand.

b. Reduce costs

Reasonably increasing Ku means that the same power transmission can be achieved without increasing the size of the magnetic core. This reduces the demand for larger size magnetic cores and lowers the cost of magnetic cores. Meanwhile, efficient window utilization may also reduce the waste of winding materials, further saving costs. Therefore, optimizing Ku is an important means of balancing performance and cost.

c. Improve heat dissipation performance

When Ku is low, the winding is sparsely distributed within the window, which may lead to uneven magnetic field distribution and local heat concentration. Optimizing Ku and filling the window space reasonably in the winding can help improve the magnetic field distribution, reduce the AC resistance of the winding, minimize winding losses, thereby enhancing heat dissipation performance and ensuring stable operation of the equipment.

5.Methods and Practices for Optimizing Ku

a. Adopting advanced winding technology

By utilizing advanced equipment such as automatic winding machines, more precise and compact winding can be achieved, avoiding the problems of looseness and unevenness that may occur during manual winding, and effectively improving the utilization of window space. At the same time, some special winding processes, such as segmented winding and staggered winding, can also optimize the winding layout and improve Ku according to specific design requirements.

b. Choose appropriate wires and insulation materials

By using high conductivity wires, thinner wires can be used under the same current carrying capacity to arrange more turns of windings in the window and increase Ac. At the same time, new thin insulation materials such as nano insulation films are selected to ensure insulation performance while reducing the space occupied by insulation materials and improving Ku.

c. Optimization design of magnetic core

Select magnetic cores of appropriate shape and size based on specific application scenarios and performance requirements. For some designs with high Ku requirements, customized non-standard magnetic cores can be considered to optimize the shape and size of the magnetic core window to achieve the best window utilization effect.

The window utilization coefficient Ku runs through the entire process of transformer and inductor design, profoundly affecting the performance, cost, and reliability of electromagnetic components. By deeply understanding the principle of Ku, accurately calculating its values, comprehensively analyzing influencing factors, and adopting reasonable optimization methods, it is possible to design transformers and inductors with better performance and lower costs, promoting the continuous development of power electronics technology.

Post time: Jun-24-2025